NEWS

The History and Evolution of Metal Logos in the Automotive Industry

Writer:admin Time:2025-03-07 15:48 Browse:℃

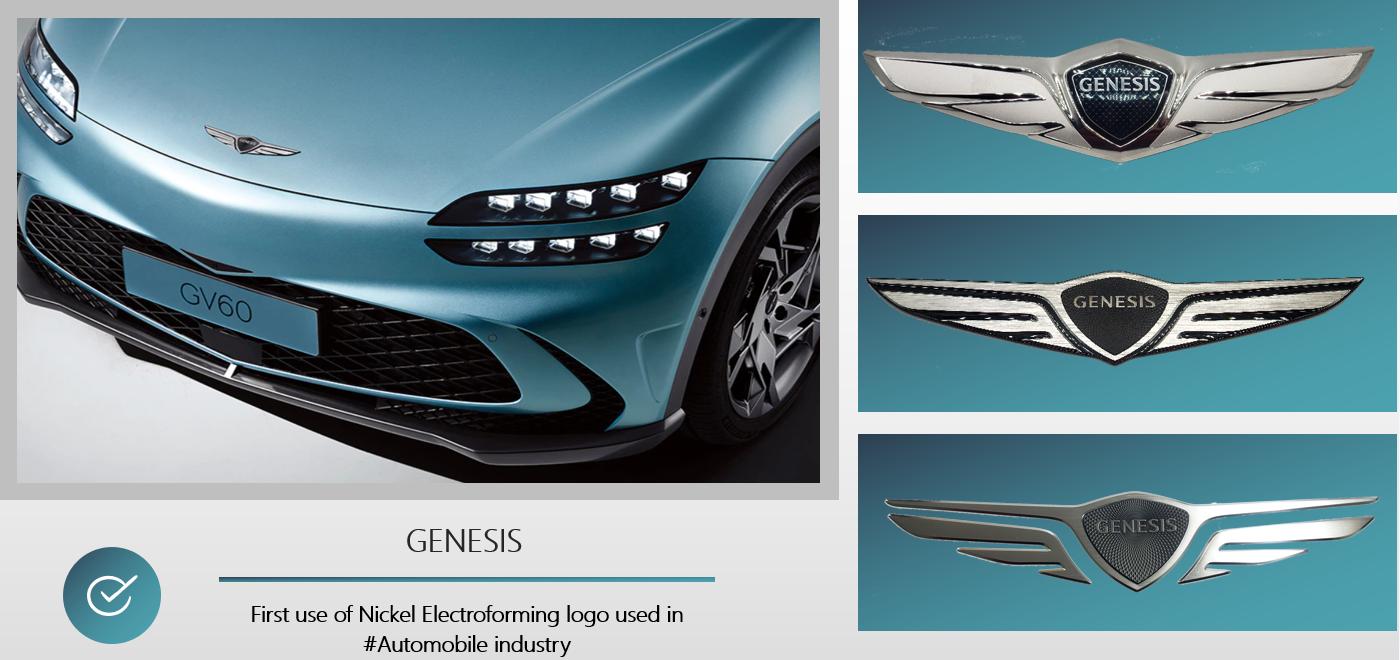

The automotive industry is more than just vehicles; it’s about symbols of identity, status, and aspiration. Among these symbols, the metal logo stands out as one of the most recognizable features on a car. Over the decades, these logos have evolved significantly, shaped by design trends, manufacturing techniques, and consumer preferences.

Early Days of Automotive Logos

In the early days of automobiles, logos were simple, often handcrafted from brass or copper, with straightforward designs. For instance, early Ford logos were merely the word "Ford" on an oval background. As the industry grew, logos became more intricate, often integrated into the front grille or hood. Manufacturers began using more durable chrome-plated metals to ensure logos could withstand the elements while maintaining their shine.

The Rise of Metal Logo Manufacture in China

By the late 20th century, China emerged as a global hub for metal logo manufacture. Chinese manufacturers gained prominence for their cost-effectiveness and ability to produce at scale, supplying metal logos to both domestic and international automakers. Qingdao Dadong Electronics Co., Ltd., established in 1995, became a leader in this space. With 30 years of experience in metal logo and film research and production, Dadong excels in using nickel electrocasting technology to create high-quality, ultra-thin, and corrosion-resistant metal logos.

China is a primary producer of metal logos, offering a wide range of customization options like metal badges and car emblems to meet global demands. Dadong Electronics leverages its patented nickel electrocasting technology to produce logos thinner than 1mm, passing 66-hour acid fog tests for durability.

Advancements in Manufacturing Techniques

Manufacturing techniques have advanced significantly. Traditional methods like die-casting or stamping were limited in design complexity and thickness. Nickel electrocasting, however, involves depositing a thin layer of nickel onto a substrate, creating intricate, durable logos that are thinner, lighter, and more corrosion-resistant than those produced by conventional methods.

Modern Design Trends

Today, metal logos are characterized by sleek, minimalist designs. With the rise of electric vehicles (EVs) and sustainable practices, logos must be lightweight yet durable. Manufacturers increasingly integrate logos into car bodies or headlights, requiring higher precision and quality in production.

Looking Ahead

China remains a leader in metal logo manufacture in China, and companies like Dadong Electronics are adapting to the future demands of the global automotive market through research, automation, and sustainability efforts. The history and evolution of metal logos in the automotive industry reflect trends in design, technology, and consumer preferences, with Chinese manufacturers playing a pivotal role.

CATEGORIES

LATEST NEWS

CONTACT US

WhatsApp: +8617685841638

Tel: +8617685841638

Email: guanweiwei@dadonglogo.com

Addr: 7 Tonghe Road, Pingdu, Qingdao