NEWS

What do electroforming and electroplating processes mean? What are the differences?

Writer:admin Time:2023-06-03 13:23 Browse:℃

In the electroforming signage industry, we often hear about electroforming and electroplating. So, what do electroforming technology and electroplating mean? What are the differences? Let's introduce the production of Qingdao Dadong signage to everyone.

1、 What do electroforming and electroplating processes mean?

Electroplating:

The process of using electrolysis to form a uniform, dense, and well bonded metal or alloy deposition layer on the surface of a workpiece is relatively complicated, but it has many advantages, such as the variety of metal types deposited and the variety of colors available,

Electroforming:

The process of manufacturing or replicating metal products by depositing metal on a mold through electrolysis (which can separate the mold and metal deposits). This treatment method is used when the required parts have special surface effects such as clear and obvious polishing and etching separation lines or special sharp angles. Generally, copper material is used to make the shape of a component, and the alloy is deposited on its surface through electroplating technology. The deposition thickness is usually several tens of millimeters, and then the cavity is cut and assembled into the cavity of the mold to inject the plastic part, The products processed in this way have special effects on the edges and boundaries of several surfaces, meeting the needs of design. Usually, we see many plastic parts with clear boundaries between high gloss and etching electroplating effects after electroplating, which have high quality requirements, usually use this method for design.

2、 The difference between electroforming and electroplating

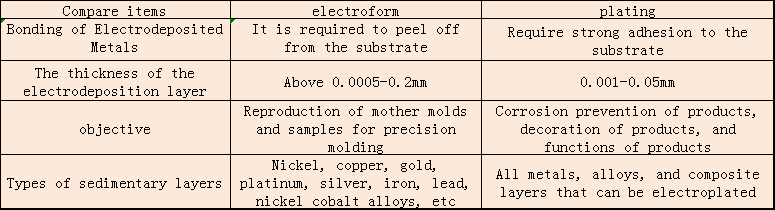

The biggest difference between electroforming and electroplating is that the electroplated product is a composite of the plated part and the product, while electroforming only uses an electrodeposited layer as the required product, ultimately separating the coating from the parent mold. The difference between electroforming and electroplating is shown in the table below:

3、 Advantages of electroforming process

1). Electroformed products have a strong metallic feel, high grade, and good wear resistance.

2). It can convert the inner surface of parts that are difficult to machine into the outer surface of the core mold, and convert difficult to form metals into easily formed core mold materials (such as wax, resin, etc.), thus making it possible to manufacture special shaped parts that cannot (or are difficult to) be manufactured by other methods

3). Being able to accurately replicate surface contours and fine lines, making it possible to perform ultra precision machining and easily produce complex shaped parts;

4). Can obtain products with high dimensional accuracy and good surface finish. The consistency of electroformed parts produced by the same core mold is good.

5). By changing the composition and working conditions of the solution and using additives, the performance of the electroformed layer can vary over a wide range to meet different needs;

6). Able to obtain high-purity metal products (electrolytic metal), multi-layer structural components, and be able to assemble various metal and non-metallic components into a whole;

4、 Types of electroforming

There are usually three types of metals used in electroforming: copper, nickel, and iron. Sometimes alloys such as gold, silver, platinum nickel cobalt, and cobalt tungsten are also used, but nickel is the most widely used electroforming. The thickness of the electroforming layer is generally 0.02-6 millimeters, and there are also thicknesses up to 25 millimeters. The dimensional error between the electric casting and the original mold is only a few micrometers.

5、 Application of electroforming

There are many applications in electroformed signs, with electroformed nickel signs being particularly popular. Applied to different civilian, commercial, and industrial products, also known as metal logo labels

CATEGORIES

LATEST NEWS

CONTACT US

WhatsApp: +8617685841638

Tel: +8617685841638

Email: guanweiwei@dadonglogo.com

Addr: 7 Tonghe Road, Pingdu, Qingdao